Language

Currency

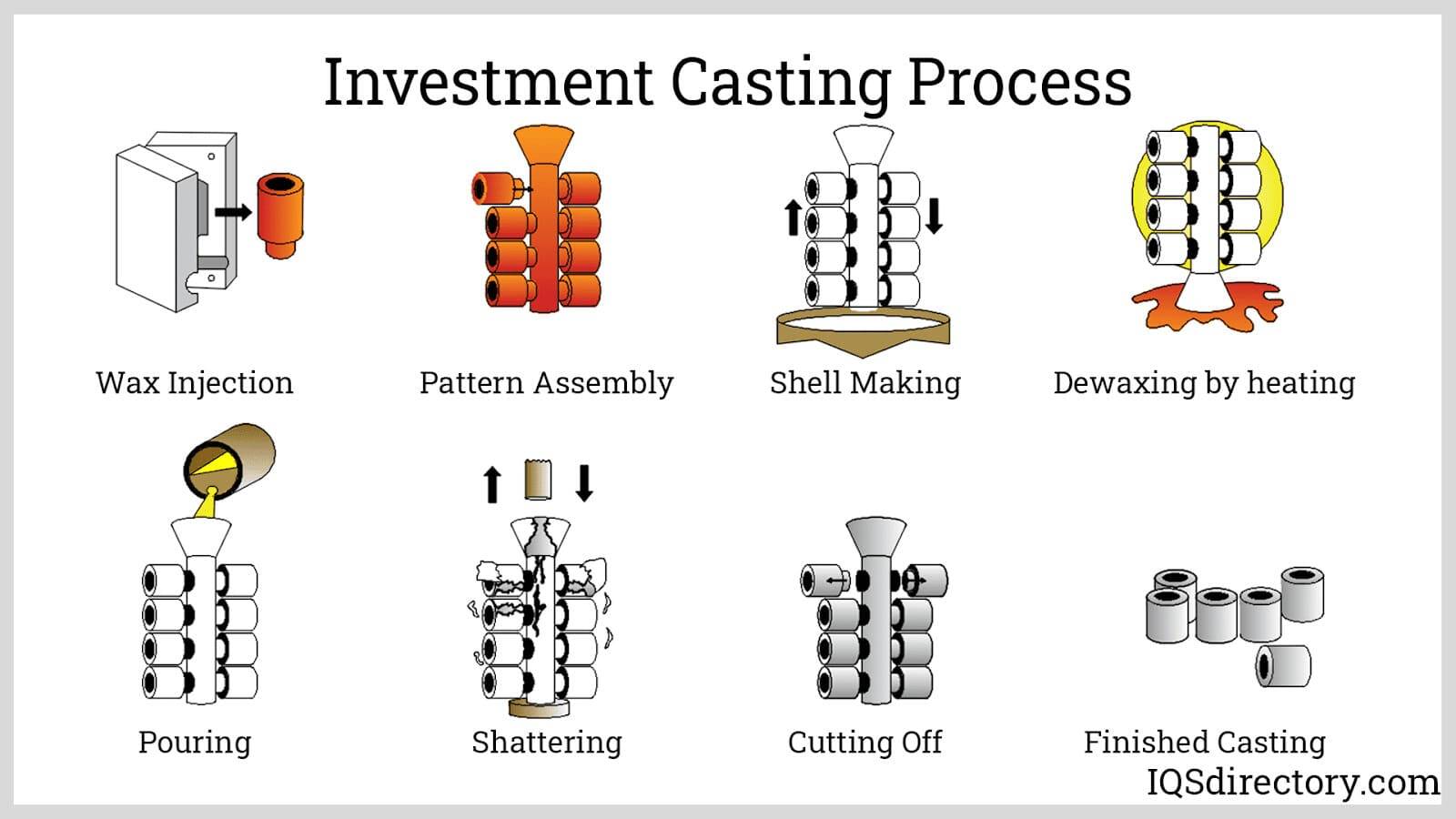

Investment casting, also known as lost-wax casting, is a highly precise and versatile manufacturing process used to create complex metal components with exceptional dimensional accuracy and surface finish. This ancient technique has been refined over centuries and is now widely employed across various industries to produce high-quality parts.

The Investment Casting Process

The investment casting process involves several key steps:

1. Creating a Wax Pattern

The first step is to create a wax pattern that is an exact replica of the desired final part. This is typically done by injecting wax into a metal die. The wax pattern is then carefully removed from the die, ensuring it retains the intricate details and dimensions of the final product.

2. Assembling the Pattern Tree

Multiple wax patterns are attached to a central gating system, forming a tree-like assembly. This gating system includes sprues and runners that will allow the molten metal to flow into each individual cavity.

3. Applying the Ceramic Shell

The assembled pattern tree is dipped into a ceramic slurry, which coats the wax patterns. This process is repeated multiple times, with each layer of slurry building up the thickness of the ceramic shell. The shell is then allowed to dry and harden.

4. Removing the Wax

Once the ceramic shell is fully hardened, it is heated to melt and drain out the wax. This leaves behind a hollow ceramic mold with a cavity that matches the shape of the original wax pattern.

5. Pouring the Metal

The ceramic mold is preheated to a high temperature to ensure it can withstand the molten metal without cracking. Molten metal, such as stainless steel, aluminum, or bronze, is then poured into the mold. The metal fills the cavity and takes on the shape of the mold.

6. Cooling and Solidification

After the metal has been poured, the mold is allowed to cool. The cooling rate can be controlled to ensure the metal solidifies evenly and without defects. Once fully cooled, the metal casting is removed from the ceramic shell.

7. Finishing the Casting

The final step involves removing any excess material, such as gates and runners, and performing any necessary finishing operations. This may include grinding, sandblasting, or heat treatment to achieve the desired surface finish and mechanical properties.

Advantages of Investment Casting

Investment casting offers numerous benefits, making it a preferred choice for many manufacturing applications:

Investment casting allows for the production of highly intricate and complex parts with tight tolerances. This makes it ideal for components that require precision, such as turbine blades, gears, and medical equipment.

The ceramic shell used in investment casting results in a smooth surface finish, often eliminating the need for secondary machining. This not only reduces production costs but also improves the overall quality and appearance of the final product.

Since investment casting produces near-net shape parts, there is minimal material waste. This is particularly beneficial when using expensive metals, as it helps to reduce material costs.

The ability to create complex parts in a single casting operation reduces the need for multiple manufacturing steps, such as welding or machining. This results in lower labor costs and faster production times.

Applications of Investment Casting

Investment casting is used in a wide range of industries, including:

Components such as turbine blades, engine parts, and structural castings are often produced using investment casting due to its ability to create lightweight, high-strength parts with complex geometries.

Investment casting is used to manufacture medical equipment, surgical instruments, and implants. The process ensures that these critical components meet the stringent requirements for precision and quality.

Investment casting is used to produce various automotive parts, such as engine components, transmission parts, and exhaust system components. The process allows for the creation of lightweight and durable parts that meet the demanding requirements of the automotive industry.

Investment casting is also used in the production of industrial equipment, machinery parts, and consumer goods such as jewelry and golf club heads. The versatility of the process makes it suitable for a wide range of applications.

Investment casting is a highly effective manufacturing process that combines precision, versatility, and efficiency. Its ability to produce complex parts with excellent dimensional accuracy and surface finish makes it an ideal choice for a wide range of industries. Whether you are looking to create intricate medical devices, lightweight aerospace components, or durable consumer goods, investment casting offers a reliable and cost-effective solution.

Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent