Language

Currency

Our Water Glass Precision Casting solution is designed to meet the unique needs of industrial customers seeking durable and high-precision cast parts. Through an efficient investment casting process, we leverage cutting-edge water glass technology to produce complex geometries with exceptional dimensional accuracy and minimal material waste. We support OEM production for various industries, including automotive, agriculture, marine, construction, and more.

The casting shown above demonstrates our precision casting capability with water glass (sodium silicate) technology. Thanks to this process, each contour is shaped accurately to match tight tolerances. Whether you require valve accessories or machinery brackets, our solution can reduce post-processing and overall production costs.

The casting shown above demonstrates our precision casting capability with water glass (sodium silicate) technology. Thanks to this process, each contour is shaped accurately to match tight tolerances. Whether you require valve accessories or machinery brackets, our solution can reduce post-processing and overall production costs.

Our castings are produced in carbon steel, low alloy steel, stainless steel, grey iron, or ductile iron, depending on your application requirements. The high structural integrity of each component ensures reliability in rugged environments. This level of excellence is ideal for industries such as agriculture machinery, where parts must withstand heavy loads, or for marine fittings requiring corrosion resistance.

Our castings are produced in carbon steel, low alloy steel, stainless steel, grey iron, or ductile iron, depending on your application requirements. The high structural integrity of each component ensures reliability in rugged environments. This level of excellence is ideal for industries such as agriculture machinery, where parts must withstand heavy loads, or for marine fittings requiring corrosion resistance.

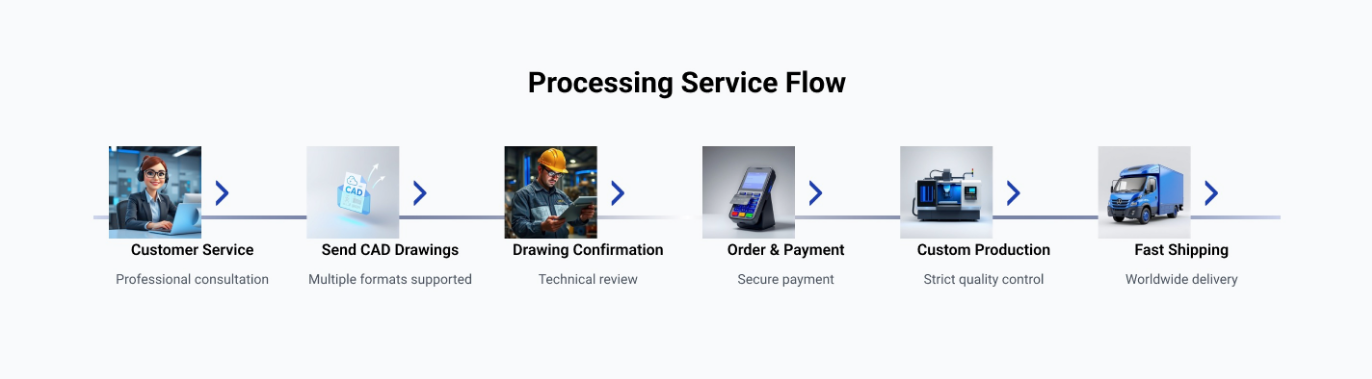

We offer custom casting production services: simply provide CAD drawings or physical samples, and our engineering team will develop a tailored manufacturing plan. Our advanced lost-wax casting processes help minimize porosity and ensure consistent quality across large production runs. With a 35-day average lead time and a capacity to handle complex designs, we make sure you receive your precision cast parts on schedule.

We offer custom casting production services: simply provide CAD drawings or physical samples, and our engineering team will develop a tailored manufacturing plan. Our advanced lost-wax casting processes help minimize porosity and ensure consistent quality across large production runs. With a 35-day average lead time and a capacity to handle complex designs, we make sure you receive your precision cast parts on schedule.

From tube fittings and valve accessories to auto parts and construction machinery components, our Water Glass Precision Casting offers flexible solutions across diverse sectors. Each piece is engineered to withstand demanding operational conditions, reducing the risk of premature wear and extending service life.

From tube fittings and valve accessories to auto parts and construction machinery components, our Water Glass Precision Casting offers flexible solutions across diverse sectors. Each piece is engineered to withstand demanding operational conditions, reducing the risk of premature wear and extending service life.

Precision Water Glass Casting and investment casting

OEM & ODM production for industrial cast components

Custom design support for valve accessories, marine fittings, tube fittings, etc.

Quality assurance and rigorous testing for each batch

Efficient logistics and 35-day average lead time

Boost your supply chain and product reliability with Water Glass Precision Casting from Ningbo Ruican Machinery Co., Ltd. Contact us today to discover how our custom casting production, technical expertise, and on-time delivery can serve all your industrial cast components needs.

Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent